The SMD passive buzzer can significantly simplify the product assembly process through its unique design and construction. Here are the main ways it simplifies assembly:

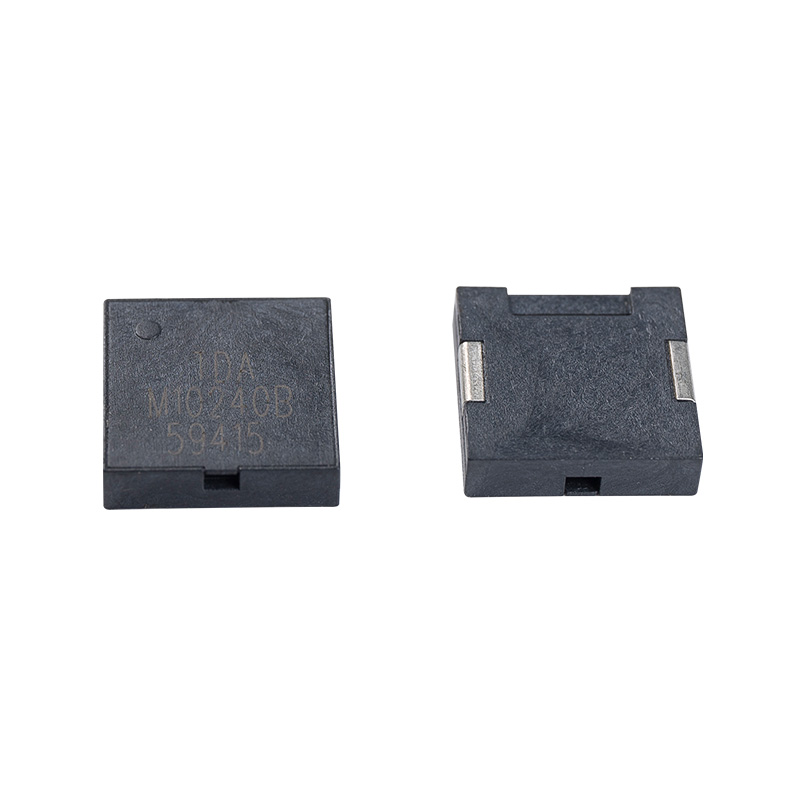

Miniaturization and integration: The SMD passive buzzer adopts a miniaturized design and can be directly mounted on the circuit board without additional installation space. Compared with traditional buzzers, it eliminates many additional fixing steps and connection lines, making the overall assembly process simpler.

Easy to solder and connect: Due to its pin design, the SMD passive buzzer can be easily connected to the circuit board by soldering or plugging. This connection method reduces complex mechanical assembly steps and simplifies the production process.

Standardization and Modularity: Many SMD passive buzzers follow certain standards and specifications, allowing them to be easily replaced or integrated into different products. This modular design allows manufacturers to quickly adjust production lines to suit the needs of different products.

Automated assembly: Due to the miniaturization and standardization characteristics of passive buzzers, they are suitable for high-speed placement machines on automated production lines. This greatly improves assembly efficiency and reduces labor costs.

Reduce external components: Some advanced SMD passive buzzers have integrated drive circuits inside, which means that additional external drive components are no longer needed, further simplifying the assembly process.

Optimized heat dissipation design: For buzzers that need to run for a long time or work under high load, a good heat dissipation design can ensure that they remain stable during work and reduce failures caused by overheating. Optimizing heat dissipation design not only improves product reliability, but also reduces maintenance costs.

EN

EN  English

English Deutsch

Deutsch 中文简体

中文简体