Yes, SMD passive buzzers have come a long way in optimizing frequency range and sound quality. These advancements are driven by the growing demand for better performance buzzers in a variety of packages, including electronics, automotive, clinical equipment, commercial systems, and more.

Manufacturers are constantly working on developing new materials that provide better magnetism and thus produce sound more efficiently. These new materials have lower losses and higher magnetic permeability, allowing SMD buzzers to produce louder and clearer sounds. .

Several design strategies have also been developed to enhance the performance characteristics of SMD buzzers. Manufacturers are using superior computer-aided design (CAD) equipment to optimize magnetic circuit layouts, resulting in higher sound output and more advanced performance. By carefully designing the location and length of magnets and coils, producers can achieve a wider frequency range and improve sound quality.

Advances in signal processing and control circuitry play a vital role in optimizing the superior sound of SMD buzzers. Manufacturers are leveraging virtual signal processing (DSP) technology to more precisely control sound generation methods. This accurately reproduces the desired frequencies and tones, resulting in better sound fidelity.

Additionally, manufacturers integrate advanced manipulation circuits into SMD buzzers to embellish their functionality. These management circuits support functions such as volume control, tone selection, and multiple sound modes, providing designers with additional flexibility in their applications.

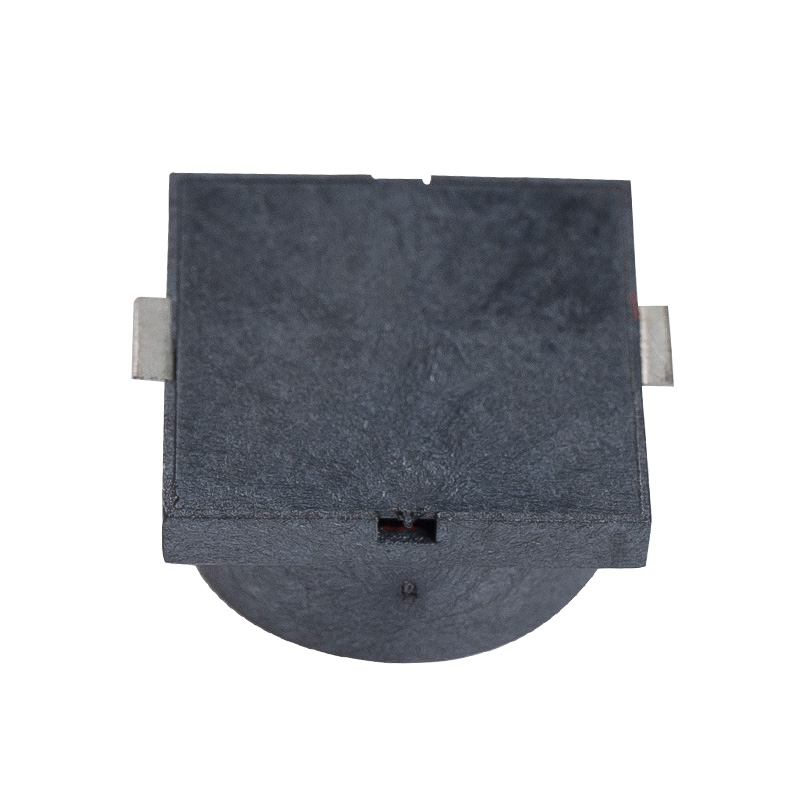

In addition to improving frequency range and sound quality, manufacturers are also working to reduce the size and intensity of SMD buzzers. This is especially important for portable electronics, where area and battery life are key factors.

Additionally, advances in manufacturing processes, including the surface mount era (SMT), have made it easier to effectively incorporate SMD buzzers into circuit boards. SMT enables computerized assembly, reducing production costs and increasing the consistency and reliability of the final product.

EN

EN  English

English Deutsch

Deutsch 中文简体

中文简体