Engineering techniques aimed at mitigating the effects of Appliance Speaker Box resonance and isolating vibrations are crucial to ensure optimal sound quality and preserve the structural integrity of the appliance. Here are several techniques that can be employed:

1. Damping Materials:

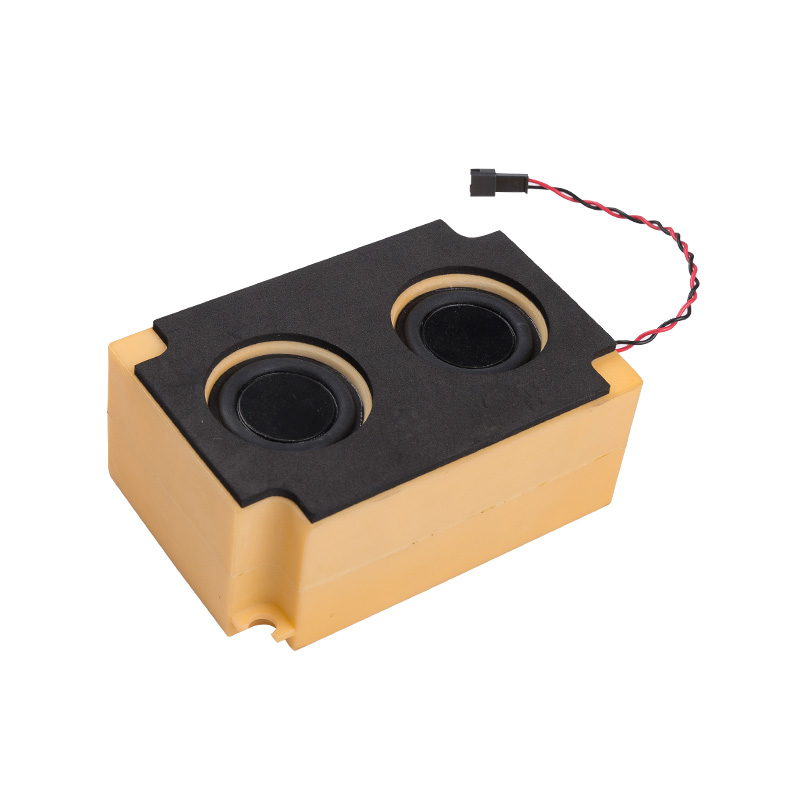

- Damping materials, such as foams, elastomers, and viscoelastic compounds, are strategically placed within the speaker box to absorb and dissipate vibrational energy.

- These materials reduce the amplitude of vibrations and prevent them from resonating, leading to cleaner sound reproduction.

2. Internal Bracing:

- Internal bracing involves adding structural elements within the speaker box to reinforce its rigidity and distribute vibrations more uniformly.

- Well-engineered bracing helps prevent panel resonances and reduces the overall vibrational impact on sound quality.

3. Decoupling:

- Isolation techniques, like mounting the speaker driver on rubber grommets or using vibration-absorbing feet, minimize the transfer of vibrations between the speaker and the appliance's chassis.

- Decoupling prevents vibrations from being transmitted to other parts of the appliance that could generate secondary resonances.

4. Resonance Frequency Analysis:

- Engineering analysis identifies the natural resonant frequencies of the speaker box and its components.

- By avoiding design elements that match these frequencies or adding damping at critical points, engineers can prevent resonances from building up.

5. Variable Density Materials:

- Materials with varying density gradients can be employed within the speaker box to disrupt the transmission of vibrations.

- These materials are designed to absorb and dissipate vibrations more effectively than uniform materials.

6. Inverse Filtering:

- Inverse filtering involves designing the cabinet structure to actively cancel or reduce resonances by introducing counteracting vibrations.

- This technique requires sophisticated engineering to achieve optimal results without introducing unwanted artifacts.

7. Vibration Isolation Feet:

- Rubber or elastomeric feet are often used to physically isolate the speaker box from the surface it rests on.

- These feet prevent vibrations from being transmitted to the appliance's structure, reducing the risk of sympathetic resonances.

8. Boundary Decoupling:

- Placing the speaker box away from surfaces, walls, or other structures prevents vibrations from coupling with those surfaces and causing secondary resonances.

9. Mass Loading and Coupling:

- Adding mass or coupling weights to specific parts of the speaker box can shift resonances to less problematic frequencies or reduce their impact.

10. Finite Element Analysis (FEA):

- Advanced engineering techniques like FEA can simulate the vibrational behavior of the speaker box and identify potential resonance points.

- This analysis guides design modifications to minimize these resonances.

11. Acoustic Insulation:

- Insulating materials placed within the speaker box can absorb and attenuate vibrations that could generate resonances.

- These materials may also have acoustic benefits by reducing sound transmission to the appliance's exterior.

12. Quality Control and Testing:

- Rigorous testing and quality control procedures are implemented to identify and address resonance-related issues during the manufacturing process.

Combining these engineering techniques ensures that Appliance Speaker Boxes are designed to minimize resonances, isolate vibrations, and maintain sound quality while preserving the appliance's structural integrity.

EN

EN  English

English Deutsch

Deutsch 中文简体

中文简体