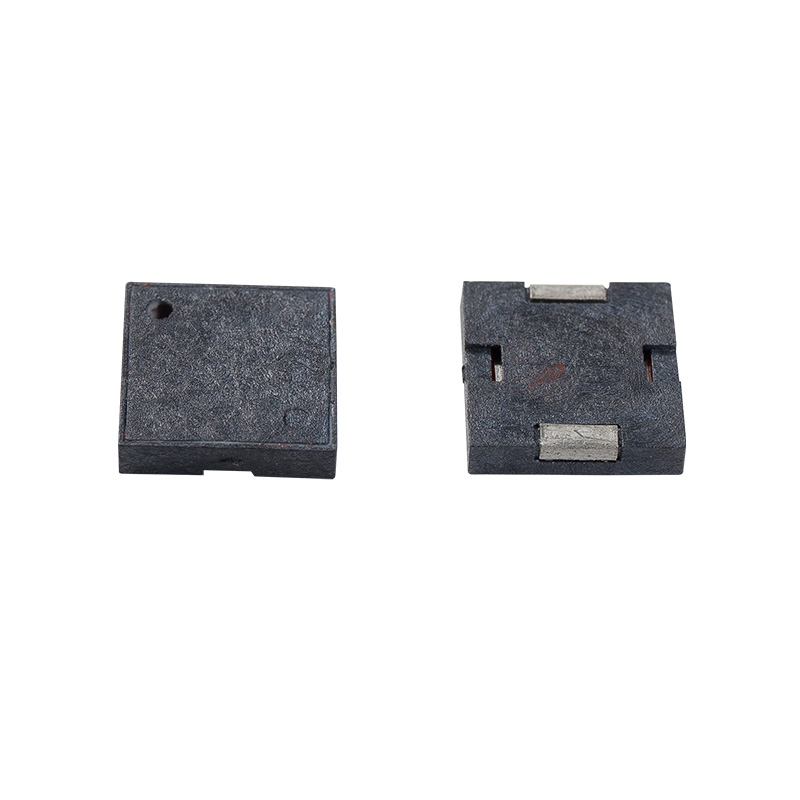

An SMD (Surface Mount Device) buzzer is an electronic sound-generating component designed for easy surface mount assembly on printed circuit boards (PCBs). It is used to produce audible alerts, tones, or signals in various electronic devices and systems. SMD buzzers have become popular in modern electronics due to their compact size, ease of assembly, and compatibility with automated manufacturing processes.

Here are the key differences between SMD buzzers and traditional through-hole buzzers:

1. Mounting Method:

- SMD Buzzer: SMD buzzers are designed to be mounted directly on the surface of a PCB using surface mount technology (SMT). They have small, flat leads or metal pads on the bottom, allowing them to be soldered onto the board's surface.

- Through-Hole Buzzer: Traditional through-hole buzzers have long leads (or legs) that are inserted through holes in the PCB, and then they are soldered on the opposite side of the board. This requires additional space for the leads to pass through the holes and creates a larger footprint on the PCB.

2. Size and Footprint:

- SMD Buzzer: SMD buzzers are significantly smaller and more compact compared to traditional through-hole buzzers. Their smaller size allows for space-saving designs and makes them ideal for compact electronic devices.

- Through-Hole Buzzer: Through-hole buzzers are generally larger and have a bulkier form factor due to their long leads.

3. Automated Assembly:

- SMD Buzzer: SMD buzzers are well-suited for automated assembly processes, such as pick-and-place machines used in high-volume manufacturing. They are placed on the PCB automatically, reducing assembly time and cost.

- Through-Hole Buzzer: Through-hole components require manual assembly or additional steps for automated insertion, which can be more time-consuming and labor-intensive.

4. Versatility:

- SMD Buzzer: SMD buzzers come in various sizes and configurations, making them versatile and suitable for a wide range of applications, including consumer electronics, automotive, medical devices, and more.

- Through-Hole Buzzer: Through-hole buzzers are also available in different types, but their larger size may limit their use in compact devices or densely populated PCBs.

5. Lead Length and Stability:

- SMD Buzzer: SMD buzzers have shorter leads or metal pads, which offer better electrical connection and mechanical stability on the PCB.

- Through-Hole Buzzer: The longer leads of through-hole buzzers can be more susceptible to mechanical stress and vibration.

Overall, SMD buzzers offer numerous advantages over traditional through-hole buzzers, making them a popular choice in modern electronics manufacturing for their small size, ease of assembly, and compatibility with automated processes. Their compact design and versatility allow for efficient use in a wide range of applications, contributing to the advancement of electronic devices and systems.

EN

EN  English

English Deutsch

Deutsch 中文简体

中文简体