SMD Buzzer Passive, like any electronic component, has the potential to cause electromagnetic interference (EMI) if not properly designed and implemented. However, manufacturers take measures to minimize EMI from SMD buzzers and make them compliant with electromagnetic compatibility (EMC) standards.

Here are some factors to consider regarding EMI and SMD Buzzer Passive:

1. EMC Compliance:Reputable manufacturers design their SMD buzzers to meet EMC standards and regulations to ensure that they emit minimal electromagnetic interference and are less susceptible to external interference.

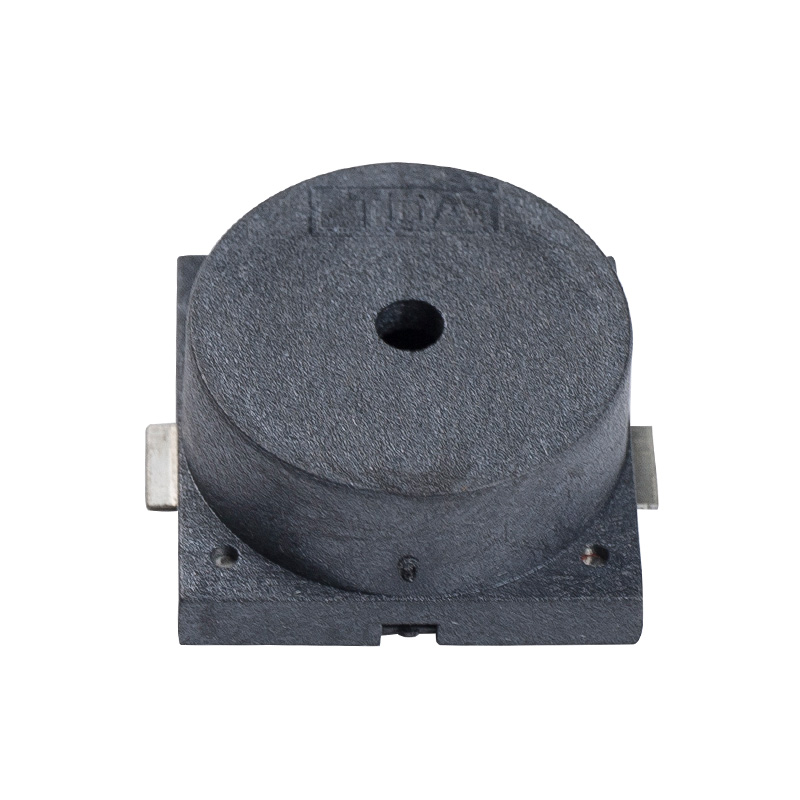

2. Shielding:Some SMD buzzers come with built-in shielding or have their components enclosed in a metal or conductive casing. Shielding helps contain the electromagnetic emissions and reduces the risk of interfering with nearby equipment.

3. Grounding and Layout: Proper grounding and careful PCB layout can also help mitigate EMI. Ground planes and appropriate signal routing can reduce the chances of unwanted electromagnetic radiation.

4. Filtering:Incorporating EMI filters in the design can help suppress unwanted frequencies and reduce the chances of interference.

5. Component Placement:The location of the SMD buzzer on the PCB matters. Placing it away from sensitive components or circuits can minimize the risk of interference.

6. EMI Testing:Manufacturers subject their products, including SMD buzzers, to rigorous testing to verify their EMI performance and ensure they meet industry standards.

7. Application Considerations:The potential for EMI depends on the specific application and the surrounding environment. Certain applications, such as medical devices or aerospace equipment, may have stricter EMI requirements than others.

By following proper design guidelines, using high-quality components, and adhering to EMC standards, the risk of SMD Buzzer Passive causing significant electromagnetic interference to other equipment can be effectively minimized.

EN

EN  English

English Deutsch

Deutsch 中文简体

中文简体